Applications Of Bismuth Copper Alloys

Posted by Admin on November, 22, 2023

Given its natural condition and its ability to form compounds, bismuth was clearly understood even in ancient times. However, it was mistaken for other metals, including lead, antimony, and tin, for a long time. It was not properly acknowledged as a distinct metal. By the middle of the 18th century, bismuth had gained recognition as a distinct ore. To learn more about bismuth copper alloy or bismuth bronze, keep reading.

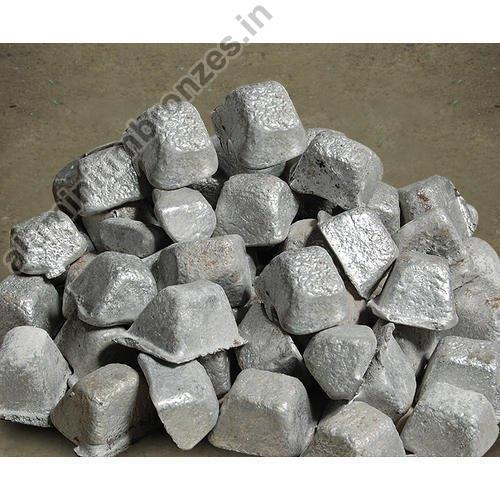

What are Bismuth Copper Alloys?

Another name for bismuth copper alloy is lead-free brass and bronze. It usually contains 1-6% bismuth, 1% nickel, 2-4% tin, and zinc, along with trace amounts of other metals.

High thermal conductivity, corrosion resistance, safety for drinking water applications, and interchangeability with previous alloys are some of the qualities of bismuth bronzes. It implies that non-compliant parts can be swapped out for bismuth bronze. Much like leaded bronzes, it may be cast, brazed, soldered, and connected. Bismuth copper alloy exporters proclaim its numerous applications in automobile, fittings, and automotive industries.

Applications of Bismuth Copper Alloys

Automotive Sector:

Fuse Elements: The production of fuse factors for automobile electrical systems involves the use of bismuth copper alloys. These alloys can provide a lower melting point. This guarantees that the fuse breaks and cuts off the circuit when exposed to excessive heat or cutting. This mechanism protects electric machinery from harm.

Thermal Switches: In the automotive industry, thermal switches are made of bismuth copper alloys. These switches provide precise temperature control for a variety of applications, such as cooling fans and engine management systems. They open or close circuits in response to temperature changes.

Low-Temperature Soldering: While joining electronic components in cars, bismuth copper alloys can be utilised for low-temperature soldering programmes. These alloys prove to be particularly advantageous for soldering heat-sensitive components.

Fittings Industry:

Low-melting Pipe Joints: Bismuth copper alloys are ideal for making low-melting pipe joints, which are especially useful in plumbing applications. These alloys make it easier to connect plumbing systems in a solid and leak-proof manner. Many bismuth copper alloy exporters from India recommend its use.

The Automation Sector:

Temperature Controls: In the automation sector, bismuth copper alloys are used to build thermal management systems. These alloys are valuable in automation systems where temperature tracking is essential. They may be utilised to create switches and controls that respond to specific temperature thresholds.

Fusible Links: Bismuth copper alloys are employed in automation structures to make fusible links, which break when exposed to high temperatures. These linkages serve as safety precautions. They guarantee the termination or activation of particular tactics as necessary.

Low-Temperature Casting and Moulding: In the automation sector, bismuth copper alloys can be used in low-temperature casting and moulding techniques. It makes it easier to produce prototypes and moulds. Contact bismuth copper alloy exporters which allows for more layout and manufacturing flexibility.

Conclusion

The increased lubricity of the added bismuth gives bismuth bronze excellent machining properties. They pour easily into moulds and are impervious to corrosion from seawater. Because of their lower melting points and specific temperature-related properties, bismuth copper alloys are often chosen. They are useful in circumstances where more conventional materials with higher melting factors are not appropriate.

Search

Category

- Chromium Copper Round Bar (2)

- Germanium Tin Master Alloy Suppliers (2)

- Copper Phosphorus In India (1)

- Seam Welding Wheels Manufacturer (1)

- Applications Of Germanium Tin Master Alloy (1)

- Gets The Effective Machine From Seam Welding Wheels Manufacturer (1)

- Industrial Metal Products (1)

- Aluminum Bronze Rods (1)

- Aluminium Based Master Alloys In In India (1)

- Applications Of Bismuth Copper Alloys (1)

- View More

Recent Posts

Leave a Comment