10 Kilogram (MOQ)

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Type | Tin Alloys |

| Diameter | 0-10mm |

| Click to view more | |

Product Details

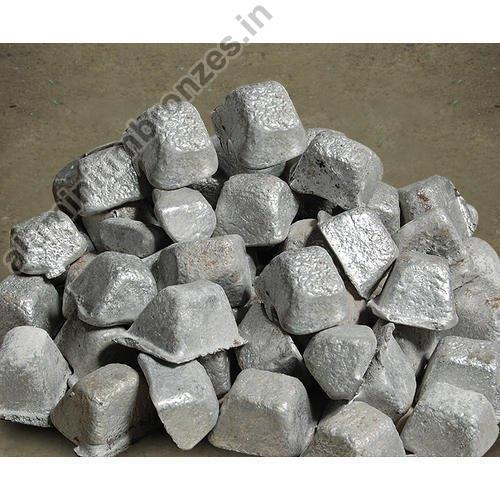

Tin, zinc, manganese, silicon, copper, rare earth elements, and zirconium are frequently used in the production of magnesium alloys by Tin Magnesium Master Alloys Manufacturer supplier and exporter at Aluminium Bronzes, which are combinations of magnesium (the lightest structural metal) and other metals. The hexagonal lattice structure of magnesium alloys has an impact on their basic characteristics.

Tin Magnesium Master Alloys manufacturer in Meerut and Uttar Pradesh provides Magnesium alloys that are primarily employed as cast alloys because plastic deformation of the hexagonal lattice is more challenging than that of cubic latticed metals like aluminium, copper, and steel. However, research into wrought alloys has increased significantly since 2003. Die-cast magnesium is also utilized for camera bodies and parts in lenses; cast magnesium alloys are used for many parts of contemporary autos and have been employed in several high-performance vehicles.

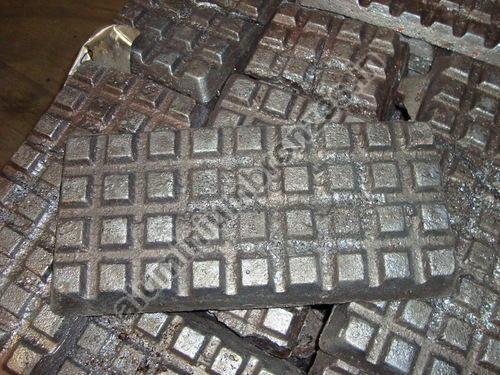

We asTin Magnesium Master Alloys manufacturer in Indiaprovide a broad selection of Copper & Tin Master Alloys, which are extensively used in the production of premium copper rods and extrusions. These goods come in wooden boxes or 500 kg steel drums and can be found as shots, waffle plates, powder, and ingots. These master alloys are also utilized in automotive pistons as a grain refiner.

In a wide range of structural applications, magnesium master alloys are utilized in the automotive, aerospace, electronics, and consumer goods industries. It is generally known that rare earth metals are efficient alloying components for magnesium alloys, particularly in terms of creep resistance at high temperatures. Because there is a significant difference between magnesium and rare earth, it is highly challenging to extract rare earth directly from the unique magnesium alloy.