Tin Based Master Alloys

Leading Manufacturers, Exporters, Wholesaler, Distributor, Retailer of Germanium Tin Master Alloy, Nickel Tin Master Alloy, Nickel Tin Master Alloy manufacturers & suppliers, Phosphor Tin Master Alloy, Tin Magnesium Master Alloys and Tin Nickel Master Alloy from Meerut.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Type | Master Alloy |

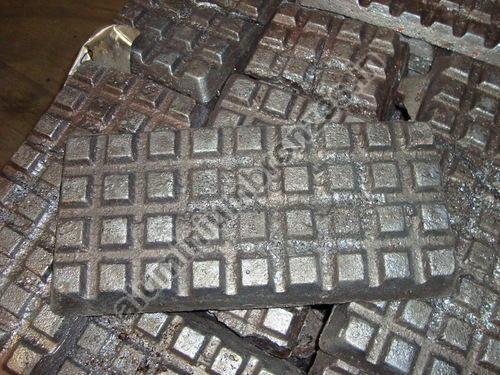

| Material | Aluminium |

| Shape | Rectangular |

| Application | Aircraft, Electrical Appliances, Increase Fluidity |

| Technics | Extruded |

| Width | 1200mm |

The most common use for the Germanium-Tin (1%) master alloy is the production of semiconductors. Transistors and integrated circuits both employ germanium.It serves as a catalyst as well as an alloying agent. Additionally, it is utilized in infrared spectroscopes and detectors. Germanium and tin, both of which are found in group 14 of the periodic table, are combined to form the alloy germanium-tin by germanium tin master alloy manufacturer and supplier.

There is a narrow range of compositions under which it is thermodynamically stable. Despite this restriction, it provides useful features for silicon-integrated optoelectronic and microelectronic semiconductor device band gap and strain engineering. You can always trust Aluminium Bronzesto get good deals on the alloy. We are also aware of the market as we are renowned germanium tin master alloy, exporters in the country.

The carrier mobilities of germanium-tin alloys are higher than those of silicon or germanium. In high-speed metal-oxide-semiconductor field-effect transistors, it has therefore been suggested that they can be employed as a channel material. Additionally, because the alloys have a higher lattice constant than germanium, they can be used as stressors to increase the carrier mobility of germanium channel transistors.

Germanium-tin alloys transform into direct gap semiconductors with efficient light emission, making them suitable for the creation of lasers. On-chip optical communication is made possible by the ability to incorporate such lasers directly onto silicon microelectronic devices since the component elements are chemically compatible with silicon.

Even though research in this field is still ongoing, the low-temperature operation of germanium-tin lasers has already been proven. There have also been reports of germanium-tin light emitting diodes that operate at room temperature. We are the best germanium tin master alloy manufacturer in Uttar Pradesh and Meerut to offer you the top-grade alloy.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Tin Alloy |

| Color | Silver |

| Application | Automotive Industry |

| Grade | ANSI, AS, ASME, ASTM |

| Country of Origin | India |

| Surfae Finishing | Polished |

200 kgs (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Distributor |

| Material | Tin Alloy |

| Color | Silver |

| Application | Fittings |

| Certification | ISO 9001:2008 Certified |

| Grade | ASME, ASTM, DIN |

| Feature | Accuracy Durable, Corrosion Resistance, High Quality |

| Payment Terms | D/P, T/T, Western Union |

| Packaging Details | 500 Kgs Steel drums |

Ni-T, It introduces nickel in the alloy and acts as a grain refiner and dross inhibitor. Because of its good frictional and contact resistance, it is plated on frictional parts.

| Business Type | Manufacturer, Exporter, Supplier, Distributor |

| Material | Phosphor, Tin |

| Shape | Ingot |

| Application | Automotive Industry |

| Certification | ISO 9001:2008 Certified |

| Grade | ASME, ASTM, BS, DIN |

| Feature | Accuracy Durable |

| Type | Tin Alloys |

| Country of Origin | India |

| Phosphorus | 5% |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Packaging Details | Steel Drums |

Tin Phosphorus is used while producing tin solders. It introduce phosphorus in the alloy and acts as a flux, grain refiner and dross inhibitor.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Type | Tin Alloys |

| Diameter | 0-10mm |

| Thickness | 10-15mm |

| Application | Automobiles, Automotive Industry |

| Feature | Accuracy Durable |

| Surfae Finishing | Polished |

| Phosphorus Content | 5% |

Tin, zinc, manganese, silicon, copper, rare earth elements, and zirconium are frequently used in the production of magnesium alloys by Tin Magnesium Master Alloys Manufacturer supplier and exporter at Aluminium Bronzes, which are combinations of magnesium (the lightest structural metal) and other metals. The hexagonal lattice structure of magnesium alloys has an impact on their basic characteristics.

Tin Magnesium Master Alloys manufacturer in Meerut and Uttar Pradesh provides Magnesium alloys that are primarily employed as cast alloys because plastic deformation of the hexagonal lattice is more challenging than that of cubic latticed metals like aluminium, copper, and steel. However, research into wrought alloys has increased significantly since 2003. Die-cast magnesium is also utilized for camera bodies and parts in lenses; cast magnesium alloys are used for many parts of contemporary autos and have been employed in several high-performance vehicles.

We asTin Magnesium Master Alloys manufacturer in Indiaprovide a broad selection of Copper & Tin Master Alloys, which are extensively used in the production of premium copper rods and extrusions. These goods come in wooden boxes or 500 kg steel drums and can be found as shots, waffle plates, powder, and ingots. These master alloys are also utilized in automotive pistons as a grain refiner.

In a wide range of structural applications, magnesium master alloys are utilized in the automotive, aerospace, electronics, and consumer goods industries. It is generally known that rare earth metals are efficient alloying components for magnesium alloys, particularly in terms of creep resistance at high temperatures. Because there is a significant difference between magnesium and rare earth, it is highly challenging to extract rare earth directly from the unique magnesium alloy.

| Business Type | Exporter, Supplier |

| Country of Origin | India |

| Type | Tin Alloys |

| Diameter | 10-20mm |

| Thickness | 0-5mm |

| Application | Automobiles, Automotive Industry |

| Feature | Accuracy Durable |

| Nickel Content | 5% |

Premier Ingots and Metals Pvt Ltd are an experienced and distinguished exporter and supplier of high-quality Non-Ferrous Metal Alloys. Automobile and automotive industries are in dire need of products like Tin Nickel which is a hard and ductile metal. Owing to its unique qualities, it is also utilized for vacuum and foundry melting applications. Regarded as one of the leading Tin Nickel Master Alloy Suppliers in Uttar Pradesh, our company is paving its way to becoming the global leader in the coming years.

We offer tin Nickel Master Alloy with a thickness of 0 to 5 mm and a diameter of 10 to 20mm. It has a high melting point and is magnetic at room temperature. Tin Nickel Master Alloy is also widely used in recharging batteries, stainless steel, and other alloys. Being an experienced and outstanding tin nickel master alloy exporter in India, we offer the customized solution as per the requirements of the customers.

Our offered product range is manufactured after passing adequate control processes using the latest machines. The Tin Nickel master alloy is corrosion resistant and alloys with chromium to give resistance against oxidation. These metals are manufactured to improve processes for refining final products. Due to its wide variety of alloying qualities, it can resist high temperature and low coefficient of expansion.

We are serving the demand of various customers and offer a unique range of master alloys to our customers. Our experienced experts are committed to maintaining the highest level of customer service making us the top Tin Nickel Master Alloy Exporter from India. We are manufacturing superior quality metals that are verified on various parameters. Our products are strong, ductile, weather resistant and highly demanded its unique features with finely finished and high density. So, if you are looking for Tin Nickel master alloy for your industry, then call us for more information.