100 Kilogram (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Distributor |

| Country of Origin | India |

| Pressure | High Pressure |

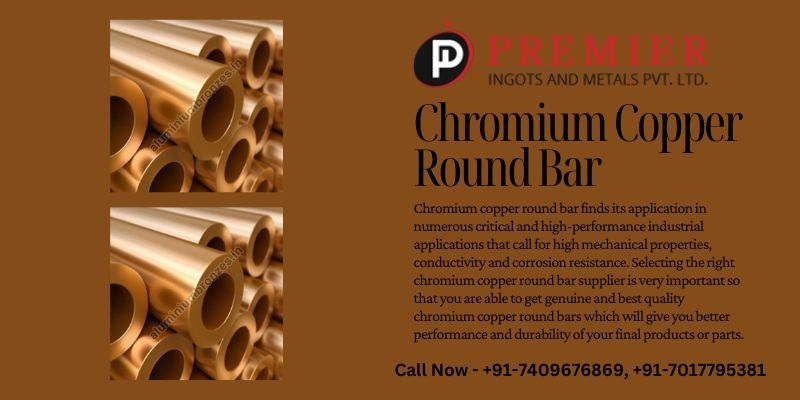

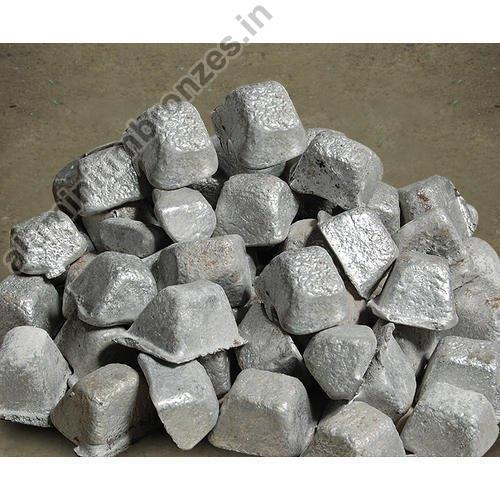

| Material | Aluminum Bronze |

| Click to view more | |

Product Details

Corrosion Resistance

Yes

Surface Finishing

Polished

Rust Proof

Yes

Speaciality

Investment Casting, Casting Approved

Aluminum Bronzes / Cast Aluminium Bronze Alloys are a combination of high strength and corrosion resistance materials which makes them one of most important engineering materials for highly stressed components that are used in highly corrosive environments besides providing optimum wear and abrasive resistance. Continuous Cast Aluminium Bronze Alloy is the form of Aluminium Bronze Alloys.

Applications

- Chemical Industry

- Petrochemical Industry

- Desalination Plant Industry

- Marine Industry

- Off-shore Industry

- Shipboard Plant Industry

- Power Generation Industry

- Aircraft Industry

- Automotive Industry

- Railway Engineering Industry

- Iron and Steel Making Industry

- Electrical Manufacturing Industry

- Building Industries

Type of Alloys

- Single-Phase Alpha Alloys - These have a good ductility and are suitable for extensive cold working. CA102 is typical of this type - Alloys containing 3% iron, such as CA106, are single phase up to over 9% aluminium.

- The Duplex Alloys containing from 8% to 11% - aluminum usually with additions of iron and nickel to give higher strengths

- Casting Alloys :

AB1/ CuAl10Fe3

AB2/ CuAl10Fe5Ni5/ CC 333G - Wrought Alloy :

CA104/ CuAl10Fe5Ni5/ C63200

CA105/ CuAl10Fe3/ C63000

Indian Standard : IS 10569 – 1983

- Casting Alloys :

- The Copper Aluminium Silicon Bronzes have lower magnetic permeability:

- Casting Alloys :

AB3/ CuAl6Si2Fe - Wrought Alloy :

CA107/ CuAl6Si2/ C64200

Indian Standard : IS 10723 – 1983

- Casting Alloys :

Mechanical Properties

| UNS | BS | Tensile Strength N/mm2 | Proof Stress N/mm2 | Elongation % | Hardness HB |

| C61000 | CA 102 | 540 – 590 | 440 – 510 | 25 – 40 | 130 – 170 |

| C62300 | CA 103 | 520 | 215 | 22 – 30 | |

| C63200 | CA 104 | 650 – 700 | 320 – 400 | 10 – 12 | 200 – 220 |

| C63000 | CA 105 | 550 – 690 | 275 – 345 | 05 – 12 | |

| C61300 | CA 106 | 485 – 550 | 240 – 345 | 30 – 45 | 150 – 170 |

| C61900 | 540 – 620 | 255 – 345 | 15 – 20 | ||

| C62400 | 620 – 655 | 275 – 310 | 10 – 12 | ||

| C64200 | CA 107 | 515 – 620 | 220 – 310 | 09 – 20 | 140 – 170 |

Chemical Composition

| C61000 | C62300 | C63200 | C63000 | C61300 | C61900 | C62400 | C64200 | |

| Aluminium | 38511 | 8.5-11.0 | 8.7-9.5 | 9.0-11.0 | 6.0-7.5 | 8.5-10.0 | 10.0-11.5 | 6.3-7.6 |

| Copper | Remainder | Remainder | Remainder | Remainder | Remainder | Remainder | Remainder | Remainder |

| Iron | 0.5 | 2.0-4.0 | 3.5-4.3 | 2.0-4.0 | 2.0-3.0 | 3.0-4.5 | 2.0-4.5 | 0.30 Max |

| Nickel Incl Cobalt | 1.0 Max | 4.0-4.8 | 4.0-5.5 | 0.15 Max | 0.25 Max | |||

| Manganese | 0.50 Max | 1.2-2.0 | 1.5 Max | 0.20 Max | 0.30 Max | 0.10 Max | ||

| Silicon | 0.1 | 0.25 Max | 0.10 Max | 0.25 Max | 0.10 Max | 0.25 Max | 1.5-2.2 | |

| Tin | 0.6 Max | 0.20 Max | 0.20-0.50 | 0.6 Max | 0.20 Max | 0.20 Max | ||

| Zinc Max | 0.2 | 0.3 | 0.1 | 0.8 | 0.5 | |||

| Lead Max | 0.02 | 0.02 | 0.01 | 0.02 | 0.05 | |||

| Arsenic Max | 0.15 | |||||||

| Phosphorus Max | 0.015 |

Looking for "Aluminium Bronzes" ?

Kilogram